Where Can I Buy Kenny Brown Tubular Control Arms For Cobra Irs

Aftermarket rear suspension pieces are a dime a dozen; there are so many companies in the marketplace offering these items that you can dial up your favorite retailer and take your choice of literally dozens of tubular control arms for your car, regardless of whether you're cruising a belatedly-model Mustang, Camaro, or Mopar production like the Challenger or Charger.

Aftermarket rear suspension pieces are a dime a dozen; there are so many companies in the marketplace offering these items that you can dial up your favorite retailer and take your choice of literally dozens of tubular control arms for your car, regardless of whether you're cruising a belatedly-model Mustang, Camaro, or Mopar production like the Challenger or Charger.

In the interest of simplifying the process, nosotros have decided to do much of the legwork for yous in this article, where we'll discuss different materials and designs that are bachelor – with the industry'due south foremost experts. This guide should help make a better-educated decision about what'due south best for your own project, your goals, needs, and wants. For this advice we went to Maximum Motorsports, Team Z Motorsports, Kenny Brownish Performance, BMR Suspension, and Spohn Performance.

Suspension Styles

While we certainly can't embrace each and every domestic performance-automobile pause design for the purposes of this article, information technology'll exist helpful to understand some of the pop styles and how they function.

At that place are three dissimilar styles of suspension that have been used in the late-model Mustang – the four-link trailing arm system used in the '79-'04 chassis and the iii-link/Panhard Rod arrangement used in the '05-'xiv models. In add-on, the '99-'04 Cobra used an independent rear suspension which we'll touch on briefly.

GM's Third and Fourth-Gen Camaro/Firebird platform used a torque arm/Panhard bar/lower trailing arm organisation. Although the pattern was slightly different the overall concept is the aforementioned. Fifth-Gen Camaros (2010-'14) make use of an independent rear suspension with lower command artillery, trailing arms, and toe rods.

In the Mopar realm, the 2005-14 Chrysler 300C, Dodge Charger/Challenger/Magnum all use the same type of independent rear suspension – iii links on each side, with a pair of trailing arms and quartet of upper lateral control artillery (front and rear on each side).

Although the rear intermission in the Mopar products is independent, the reason y'all'd want to replace the arms is the same every bit the other platforms.

The Benefits Tin can Make You Experience Amend

Hither's a side-by-side view of the differences between an OEM bushing (lesser) and a greasable urethane bushing (top). The urethane design is much more robust and works to command axle forces as they are transmitted through the control arm.

Replacing your manufacturing plant rear control arms can provide many benefits, from improved treatment in the twisties to amend direct-line performance if the dragstrip is your thing. Manufactory command arms are typically manufactured with two things in heed – cost and ride quality.

For that reason, they are typically constructed from stamped steel forms and loaded with rubber bushings that have been designed to suck all of the route dissonance out of the chassis. In the process, those not-so-strong artillery and compliant condom bushings also suck the life and operation out of your hot ride.

By removing the safe-bushed manufacturing plant arms from the equation and replacing them with stiffer, more performance-oriented pieces, you'll gain greater experience of the route.

Depending upon which type of control arm bushing yous use, there will be an accompanying increase in road noise over stock every bit urethane bushings transmit more racket than the OEM safe pieces, and the solid rod-cease blueprint increases NVH transmission even more, but both urethane and rod-ends offering a large increase in performance capabilities over the factory items regardless of the intended use.

"All of the forces that accelerate the car, as well as much of the braking loads, pass through the rear lower command arms. In stock form, the excessive deflection allowed by the original prophylactic bushings prevents the rear axle from maintaining its correct position under the chassis. The beam is allowed to shift forwards, backwards, and sideways under the motorcar, leading to poor traction and poor handling," says Maximum Motorsports' Chuck Schwynoch.

A factory S197 Mustang command arm on the left compared with Squad Z'due south double-adjustable arm on the right. The double-adjuster in the center of the Team Z arm allows the user to ready pinion angle without removing the arm from the motorcar.

He continued, "To ameliorate handling and traction information technology is vital to control the motility of the rear axle. The central to amend axle control is in the bushing design. A proper bushing design volition provide precise location of the beam while also allowing the motion required for the suspension to part."

Upgrading the control arms on your automobile tin provide a desperate difference in performance, but it'due south also of import to make sure you lot're selecting the proper production for your situation – 1 replacement control arm pattern does Non piece of work properly in all applications.

Cloth Construction

What'southward Happening Nether There?

"Rear lower control arms, along with the upper arms, control axle rotation. All of the forces that accelerate the car pass through the rear lower command arms. The tires rotate on the pavement, moving the beam frontward. The axle pushes on the rear lower command arms, moving the rest of the machine forward. The command arms, and their bushings, must withstand those forces," Schwynoch explains.

There are three different materials typically used in control arm structure – DOM (drawn-over-mandrel) mild steel, aluminum, and chromoly steel; each material has its advantages and disadvantages in application.

DOM steel is non actually a blazon of tubing – instead, DOM is a procedure past which steel tubing is synthetic. DOM tubing has typically been electrical welded, and during the manufacturing process the steel is drawn over a mandrel which cold-works the material and gives it more than compatible dimensions relative to the inside and exterior dimensions of the tube itself.

The cold-working process makes the weld line disappear and the resulting tube to exist virtually seamless. Tubing commonly used for command arm structure is synthetic from 1020 steel, which offers 87,000 psi of tensile force and 72,000 psi of yield strength.

Rectangular DOM heavy-wall mild steel tube is as well used in some applications – its low cost and ease of fabrication make it a prime candidate for a upkeep-style control arm.

Here's another style of aftermarket Mustang rear suspension from Maximum Motorsports. It uses their Extreme Duty lower control arms, but adds a torque arm and panhard rod to the equation. In this awarding, the panhard rod controls side-to-side movement of the axle in the chassis and the torque arm controls axle rotation through the use of rigid mounts. The Third- and 4th-Gen F-Body platform uses a torque arm pattern as equipped from the factory.

CNC-machined billet aluminum is used in some applications every bit a material for control arm construction. Billet aluminum offers high strength and extremely light weight, just is not typically used in an all-out drag application every bit the fabric is not optimized for higher-horsepower cars.

"These require good engineering and design to ensure they will withstand the loads applied without declining. Dissimilar steel, aluminum has a finite fatigue life, and then that should be taken into consideration when designing annihilation made of aluminum that is load cycled," says Schwynoch.

4130 chromoly steel is lightweight – not as lightweight as aluminum, but lighter than 1020 mild steel, and has a high tensile strength of 97,200 psi along with yield strength of 63,100 psi. Information technology's easily welded with the TIG process. Chromoly has more pound-for-pound strength than balmy steel, which permits a thinner wall thickness to be used to save weight and still equal the aforementioned construction strength.

Bushing And Bearing Styles

There exists the opportunity to use a number of dissimilar materials at each end of the control arm, from rubber (which is typically present in a stock control arm) to urethane, to an all-steel rod end and even a combination of urethane and rod end.

Nearly all of the control arms on the market that are designed for street use have been constructed with the use of a urethane bushing for long life and high resistance to deflection. Squad Z Motorsports uses urethane bushings in their Street Beast lineup of command arms with great success.

"We use a proprietary urethane material in our kits. It's designed then that if you have a 1,000 horsepower street machine, you're not beating the bushings out of it every twelvemonth – we've got the highest durometer bushing that we could notice forth with the proprietary cloth, and and so far our customers have been hitting high one.thirty and low 1.40 short times regularly with the Street Beast system. With the urethane yous don't get the articulation that you'd get with a rod end, only information technology's a tradeoff for a street client – they don't want the dissonance associated with the rod stop," says Team Z Motorsports' Dave Zimmerman.

This image shows 2 of the different types of ends integrated into i command arm from Kenny Brown. On the right is a urethane bushing, which assists in quieting road noise, while the left side is a rod end that permits articulation but non deflection. Kenny Brown uses Teflon-lined rod ends to limit the transmission of road noise and reduce harsh NVH characteristics as they sell just as many break products for the street as they practice for the runway.

Some other choice for controlling the move is a combined design, like Maximum Motorsports' Heavy Duty Mustang control artillery. The chassis end of the control arm uses a unique 3-piece bushing design that allows articulation while reducing deflection and dampening the noise transmission on the chassis side, while the beam end uses a spherical bearing that allows for all of the articulation necessary. These are used in street cars making up to 400 rear-bike horsepower.

During a high-horsepower launch from a standing start, deflection in a standard urethane bushing tin can cause cycle hop – and every bit nosotros all know, wheelhop is a parts gobbling gremlin. To that stop, if you're making a substantial amount of horsepower, MM also offers their Extreme Duty control arm design that have spherical bearings at each end of the arm. Unique to this command arm design, Maximum captures the bearing in a machined sleeve. Both Heavy Duty and Extreme Duty designs use a 2-inch bore steel tube for the arm.

We can't forget the GM and Mopar machines, either. BMR Suspension and Spohn Performance produce a wide variety of products for the Brand 10 machines, including the fourth and fifth-generation Camaro among others in addition to their many Mustang offerings.

The deviation in construction and quality on this BMR Camaro 4th-Gen Camaro arm (tiptop) and the OEM arm (bottom) is substantial. No flex here!

BMR offers both non-adjustable and double-adjustable lower control arms for the 4th Gen Camaro – the non-adjustable version is bachelor with greasable polyurethane bushings in either boxed or tubular designs, while the double-adjustable version is made in the bushing and rod end versions.

The boxed design and non-adjustable tubular designs are made from mild steel, while the double-adjustable versions are made from 4130 chromoly. Rod terminate designs use QA1'due south XR-series Teflon-lined spherical rod ends.

BMR'south Pete Epple explains, "When you buy a new ready of control arms, the decision to use a polyurethane bushing or rod ends depends solely on what you will be doing with the car. If y'all primarily drive your motorcar on the street and possibly go to the rails in one case or twice a yr, a poly bushing is all you'll e'er need. Y'all'll accept a big reduction in bushing deflection over the stock rubber bushings, which volition requite a large improvement in handling and traction. The machine also won't experience equally sloppy, and the ride won't be harsh considering the poly bushing volition absorb enough NVH to retain near-stock ride quality."

High-durometer urethane bushings work well in street applications, while a rod end is ideal for racing (and the street, if you're that hardcore!). Only plan on inspecting rod ends every year if y'all race and more often if you're driving them on the street.

"If you lot are a more than hardcore enthusiast, rod ends are the way to go. Rod ends create a solid link between the rearend and chassis, and while this ways there is nothing to blot all of the fiddling bumps in the route, every bit of the car'southward power is transferred direct the tires. At BMR Suspension, nosotros also have bushing/rod end combos for the guys and gals that want the all-time of both worlds. They tin get the adjustability and improved functioning without all of the harshness associated with solid mounting the arms to the chassis," he says.

Spohn Performance uses a unique pattern in many applications centered around their Del-Sphere pivot joint.

"The Del-Sphere joints are designed to have the capabilities of a rod end, where you have the articulation, merely nosotros wanted to brand something that was greasable and rebuildable that'due south a little bit more route-friendly. Instead of the brawl sitting on a Teflon lining, information technology sits in a Delrin bushing, which helps to proceed things quieter than a rod finish. It has an adjuster ring on it for two reasons – one, and then if y'all need to replace whatsoever parts on it you lot can take it apart and rebuild information technology, and second, we accept a special tool that allows yous to loosen the set screw, tighten upward the ring a few notches, and it'south similar a brand-new articulation once more," says Spohn Functioning's Dan Brown.

Spohn'southward Del-Sphere joint incorporates a spherical brawl surrounded by Delrin bushing cups and allows the command arm to articulate, but does not permit ti to deflect. This assists in both straight-line traction besides as bind-free performance in the twisties.

Spohn Operation offers upper and lower double-adjustable command arm fitments for all of the popular years of Mustang along with the F-Body and the Chrysler LX platforms – their catalog is extensive and widely varied.

Spohn's Del-Sphere organization is included in many of their production lines, along with standard urethane-bushed not-adjustable systems and even rod-terminate systems in some applications. Spohn uses a mixture of DOM steel and chromoly steel depending upon design, and they even offer a total 4130N upgrade on some of their products.

Relocated Arm Design

Sometimes relocating the position of the control arm can make a very large difference, especially in a drag racing application. The entire point of replacing the control arm in a drag racing application is to lower the lx-foot time – a better launch volition translate into a better overall elapsed fourth dimension. In well-nigh scenarios, if you can improve the launch past one tenth of a second, yous'll proceeds two tenths of a second on the top end.

The instant center on the S197 chassis is 109 inches in front of the front end bumper as delivered from the factory, so it doesn't actually want to work so well. – Dave Zimmerman, Team Z Motorsports

The Mustang in particular benefits from intermission relocation – while the cars work well from the manufactory in moderately-powered applications, there are definite improvements that tin can be fabricated. "On the '79-'04 Mustang chassis, in that location is no instant middle point – it's not-existent. The suspension is closer to a parallel four-link, and yous need an intersect point to go fast in a straight line," says Zimmerman.

Team Z offers their Strip Series I kit for the '79-'04 Mustang, which comes with relocation brackets for the upper command arms to get the instant center in the proper location for all-out drag cars.

By using a subclass that fills the holes where the stock bushings would sit, Squad Z moves the upper arm mounting position slightly up and substantially forward to improve the instant centre location for dragstrip action, and they also triangulate the new brackets to the spot where the vibration damper mounts for improved stiffness.

Team Z'due south Strip Serial 1 '79-'04 Mustang 8.8-inch rear upper control arm bundle relocates the upper control arms to put them in the proper position for stellar dragstrip operation.

The 2005-'14 Mustang was prone to substantial wheelhop from the manufacturing plant due to the control arm location – both the upper and the lower arms can be easily moved with bolt-on parts that substantially improve functioning.

BMR Intermission, Team Z, and Kenny Brown all offer lower control arm relocation brackets along with a new upper control arm mount. The lower pieces right the anti-squat by moving the lower arm down relative to the ground. The revised upper mount design also helps to improve traction, and the BMR and Team Z pieces offer multiple mounting holes for improved dragstrip functioning, peculiarly on lowered cars. Each visitor has their own take on the gear up, and then it's best to consult with them dependent upon your intended use for the vehicle.

Kenny Brown's upper command arm module for the S197 Mustang is unique in that it uses only one pigsty on the mounting bracket, just they've designed the arm to have a slight bend in information technology. "We run our cars pretty low -the track cars sometimes even lower than street cars would exist. The curve is to clear the chassis when the machine goes over a hard bump – information technology's so the arm doesn't bottom out on the underside of the car. Our upper arm module only has i hole, and the beam anti-squat brackets merely have one pigsty. Over the years I've developed specific geometries that work pretty well. This gives the all-time combination for street, track, and dragstrip driving, so our customers don't have to figure out how to arrange it, or make a bad aligning. They just accept to drive, and it works. The same principles that I utilise to get a car out of a corner are the same principles that someone would use at the dragstrip to get a car out of the hole. It'south all about generating grip," says Kenny Brown.

Kenny Brown's S197 Mustang upper and lower arms in place on a vehicle - annotation that there are no holes in the bracketry, as Brown has found that his customers adopt to be able to bolt in their parts and get.

Kenny Chocolate-brown offers an extensive catalog of pieces for all Mustang model years with an intense focus on road racing – the company proves the product on the track. Their AGS complete suspension systems are now in their fourth generation and have been used on scores of route-race Mustangs and street cars to boot, thanks to the incredibly improved geometry.

In addition to the fact that these pieces provide great do good in the wheelhop department, they also help to provide more bite in the corners by increasing anti-squat and anti-lift to maximize traction and braking capabilities – they aren't just for elevate cars.

Kenny Brown spaces the lower command arm out on the S197 Mustang to attain a better-treatment vehicle. This is achieved by using an commencement arm and spacer package to right the rear curlicue axis.

"On the S197, the lower control arms are splayed outwards. If you were to look from the summit downwardly and extend a line from the command arms to the point of convergence, it would be behind the car. And if yous took the indicate of convergence and ran it through the roll center, that gives you lot a real roll centrality, and on the stock Mustang it points upwardly in the air," says Brown.

"We use spacers to straighten out the S197 control arms then that they are parallel to centre, which means that the scroll centrality becomes parallel to the lower control arm from the rear roll heart. I do that to punch in but a little flake of ringlet understeer, since the Mustang is notorious for having a tail that wags. The merely way to solve understeer on the track is to lift off the gas. Since everyone thinks they can control oversteer with the throttle, and ultimately that leads to 'I got it, I got it, I got it, I don't got it'. By altering the rear geometry, I have a piffling bit of roll understeer which is perfect for the average commuter. It'due south safer, more fun, and easier to bulldoze the style we set up it up."

IRS Versus Solid Rear Axle

The solid axle is at present considered ancient technology, and up until the end of the 2014 model year, the Mustang was the concluding performance auto holdover to utilise i – thus the proliferation of intermission parts for the S197 and earlier Fox-based platform that have become and then ubiquitous at dragstrips across the world.

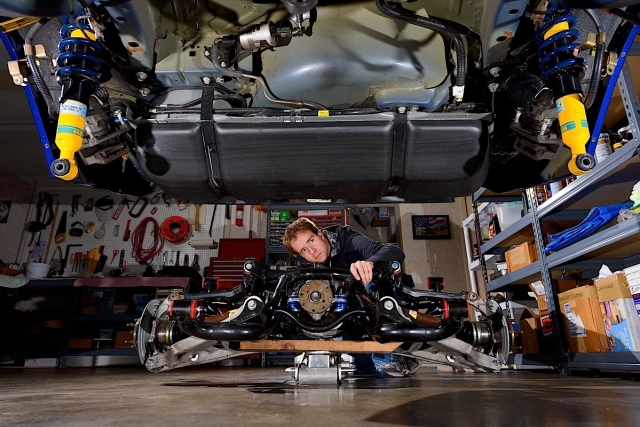

The complexity of the contained rear suspension of the '99-'04 Mustang Cobra makes it challenging to work on – there are no simple control arm replacements here. Kenny Brown makes a complete treatment package for the Mustang IRS including replacement upper and lower control arms that are designed to improve tracking and treatment while reducing unsprung weight.

Current-mean solar day performance revolves around the contained rear suspension on the Camaro chassis, forth with the Mopar performance offerings like the Challenger and Charger. The independent pause designs frequently center around a set up of track confined, which could be considered along the same lines equally the lower control artillery in the stick axle design, but a divide knuckle to concur the axle in place that's located by at least two upper links.

The Fifth-Gen Camaro uses an contained rear interruption with 4.5 links. It consists of L-shaped upper control arms that controls lateral and longitudinal move, traditional lower command arms, rear trailing arms, and toe rods. This is our Project ZL1UPED 2010 Camaro which recently received a full BMR break upgrade for road-class and street-driving activeness – you lot'll be able to read about that presently on LSXMag.com.

Where the independent rear suspension shines – and the reason the Mustang finally has 1 from the factory for 2015 – is in daily-driven applications along with road-racing. The independent rear suspension acts to follow the road much more closely than a solid beam would, keeping the tires firmly planted no thing the situation. Each wheel is able to arrange to changes in the surface without upsetting the vehicle's overall characteristics.

The reward to the solid axle design is its simplicity – it'south space-efficient and extremely inexpensive to manufacture. Only since it doesn't allow each wheel to move independently in response to bumps, solid axle-equipped vehicles are much more decumbent to chassis upset if the surface is not pristine. This is why SRA vehicles excel on the dragstrip, where the surface is flat and forgiving.

They are not nigh as proficient in road-course activity since the wheels cannot (as a office of the SRA pattern) have whatever camber angle gain during body roll. In addition, the SRA is role of the unsprung weight of the vehicle, which affects ride quality towards the negative side as the springs and dampers take to work harder to control its heft.

The Chrysler Sixty platform (Challenger/Charger/300C/Magnum) too uses an independent rear suspension, and Spohn Operation builds control artillery that replace the factory pieces in all three positions – trailing arm and both upper front and rear lateral positions.

Spohn offers both adjustable and not-adjustable control arms for the Chrysler Threescore platform to supervene upon all three control artillery in the rear of the car for improved performance. Delrin bushings are standard on both adaptable and non-adaptable artillery.

"Most of the customers we take for the LX platform are based around drag racing and street functioning, people that are lowering their cars and need to adapt the camber back out. There isn't anything from the factory that allows you to adjust the camber other than an aftermarket bushing, which doesn't provide enough aligning. We utilise Delrin bushings in these cars because the factory bushing dimension isn't very large. We wanted something that was going to exist stiff enough to exist able to put the ability to the ground, and a urethane bushing in this application might take retraction a lilliputian bit and take some of the weight transfer away," says Spohn'due south Brown.

Wrapping Upwards

The plethora of replacements bachelor to correct manufactory-designed pause deficiencies are extensive. Every bit each of the vehicle platforms discussed evolve in the performance aftermarket, the companies servicing those platforms are continually testing and refining their products to requite the finish user a wide variety of options to allow their vehicle to perform better, whether it'south on the street, at the dragstrip, or on the road class.

We couldn't possibly provide an all-encompassing listing of parts or products for every vehicle platform, just hopefully we've helped to increase your understanding of how and why the products are designed as they are. Information technology's upward to yous to determine the best product for your item awarding. Don't be afraid to brand interruption modifications to your motorcar – in every example, they will meliorate and enhance your vehicle'southward performance.

Where Can I Buy Kenny Brown Tubular Control Arms For Cobra Irs,

Source: https://www.dragzine.com/tech-stories/brakes-suspension/a-guide-to-buying-aftermarket-rear-control-arms/

Posted by: marlowlonishe.blogspot.com

0 Response to "Where Can I Buy Kenny Brown Tubular Control Arms For Cobra Irs"

Post a Comment